What are Positive and Negative Pressure Isolation Rooms, and how do they work? In this article by Richard Whitehead, we answer these questions.

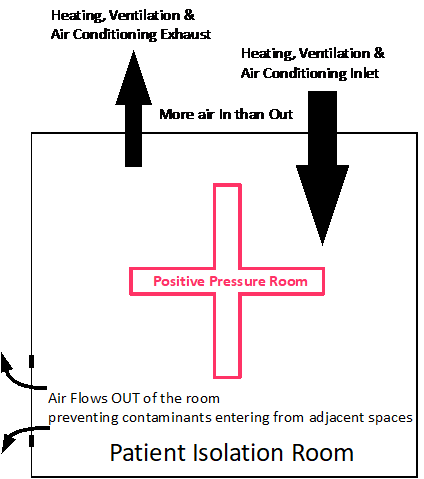

A Positive Pressure Isolation Room is designed to stop contaminants from entering the patient room. The air pressure within the room is slightly higher than that of the surrounding spaces preventing infection from entering. Incoming air may be filtered just before it enters the room.

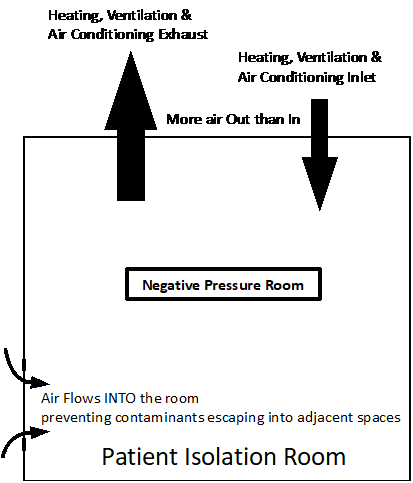

A Negative Pressure Isolation Room is designed to stop contaminants from leaving the patient room. The air pressure within the room is slightly lower than that of the surrounding spaces preventing infection from leaving. Exhaust air may be filtered just before it leaves the room.

A mechanical pressure gauge or pressure switches and lights should be placed near the entrance to the room to ensure that medical personnel are aware that the pressure system is working. An audible alarm may also be included to alert of failure.

However things are not as simple as they seem.

Opening the door for medical personnel to access the patient will temporarily stop the pressure difference which could then result in contaminants entering or leaving.

A small entrance lobby should be included in the design of these rooms to ensure that there is always the correct pressure gradient between the patient room and the outer space or corridor.

Other things to consider:

Should the lobby outer and inner doors be interlocked so that only one door can be open at any time?

If so then ensure that an emergency open device is included so that both doors can be quickly opened for emergency evacuation.

What needs to happen if the positive room pressurisation fan fails as the room may suddenly become unintentionally negative? Medical personnel must have a documented procedure.

What needs to happen if the negative room exhaust fan fails as the room may suddenly become unintentionally positive? Medical personnel must have a documented procedure.

Should the integrity of the pressurisation be added to a Building Management System with failure alarms?

If so there must be a documented procedure to ensure that medical personnel are quickly made aware of the failure and that maintenance personnel take suitable action to restore normal service as quickly as possible.

Filters to capture contaminants may be highly infectious, a process must be developed to safely replace the filters without harming the person performing the task.